If you want to only use hand tools for an entire project, one of the first work steps is ripping the board. This includes trimming cuts as well as resawing to produce thinner pieces from thick boards or even to split a log into small boards.

Regardless of the type of cut you want to make you must have a saw with rip teeth. For some applications, such as for trimming, you could perhaps use a saw with universal teeth, however, the teeth should always be quite large and the saw blade as long as possible. A quick tip: always use the entire length of the saw! That way you cut through more material in one stroke, which will make your progress significantly faster.

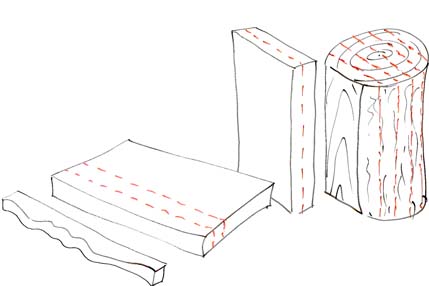

Two ways to cut a board lengthways: ripping cuts and resawing cuts

Guiding the saw through a kerf

An important technique is to create a guide for the saw using a kerf. To reduce drift in the actual separation cut, a kerfing plane can be used. If you have a circular saw to hand, you could use this to make the kerf.

The kerfing plane cuts a kerf around the edge of a board

The right saw technique for ripping cuts

It doesn’t matter if you use Japanese or Western saws as the required saw techniques are very similar. Always saw downwards on the side where you can clearly see your line. The result will be considerably better if you always saw on the diagonal and turn the workpiece often. This improves the guidance and the saw drifts less.

Trimming cuts

The following method is for detaching the wane and if you want to saw several narrow pieces lengthwise such as for chair or table legs. Traditionally, a frame saw is used for trimming cuts. In contrast to normal saw cuts (e.g. crosscuts, short formatting cuts, curved cuts), when ripping wood the saw blade is turned at right angles to the frame and the saw is guided up and down in front of the body. This type of sawing is sometimes called bow sawing. The saw is not held with one hand on a bow, but with both hands: one on the handle to turn the saw blade, and the other on the stretcher or on the other end of the bow to guide the stretcher.

It is important that you clamp the workpiece tightly in your workbench. To prevent it tilting, the bench dogs are moved so that their lip is over the workpiece to hold it down steady. The motion isn’t just up and own, but also slightly swinging, so that the saw blade moves like a jigsaw with active pendulum action — slightly forward slanting in the downward movement (cutting stroke), almost perpendicular on the upward movement (upstroke).

Classic saw mount for cutting with a frame saw

Wird zum Besäumen ein Fuchsschwanz verwendet, legen Sie das Material auf eine Sägebank oder einen Sägebock. Diese sind deutlich niedriger als eine Hobelbank, sodass Sie mit voller Körperkraft arbeiten können. Rechtshänder fixieren das Werkstück durch ihr Körpergewicht mit dem rechten Knie. Gesägt wird wie zuvor beschrieben in einer Pendelbewegung. Durch eine flache Sägenhaltung wird zunächst eine Führung geschaffen, dann wird die Säge steiler gestellt und durchgesägt. Diese beiden Arten zu sägen werden immer wieder abgewechselt.

Trimming with the panel saw on a saw bench

With Japanese saws, ripping is done standing up. The workpiece rests on one or several low trestles and is pressed down with a foot. Like sawing with a panel saw, the work angle is constantly changed.

Resawing

This technique allows you to produce sawn veneer, or cut two or more thin boards from one thick one, as well as to rip a small log into boards.

Since the section to be sawn is considerably bigger, we recommend using a kerfing plane or circular saw on the long sides at least, so that the handsaw has a better guide (this isn’t possible when splitting a log as there are no trimmed edges). Even if you’ve already cut a kerf in as a guide, always saw deeper diagonally on the side facing you. Turn the workpiece over and saw again on the clearly visible side in the kerf. This gives you better control over the cut and you can immediately recognise and correct small errors.

Regardless of which saw you use, clamp the workpiece upright if possible, so that the gravity of the saw presses down with its own weight. Most frame saws have the disadvantage that you get sideways tipping if the frame has to be extended wide to create enough space between the saw blade and the tensioning cord. In addition, the frame or the saw blade have to be swapped over frequently, for example if the thicker part doesn't go through the opening between the tensioning cord and the saw blade when you're splitting a log. A workaround to counter sideways tipping is a frame saw with one longer bow. This gives you space to hold it on both the left and right hand sides of the saw blade. Alternatively use a frame saw like a »Roubo«, if the opening next to the saw blade is big enough. You don’t get the same opening and tipping problems with a panel saw or with Japanese saws; they let you cut through workpieces of any thickness. These types of saw also come in different sizes and suitable rip-cut teeth.

Even in deep rip cuts, you still cut diagonally first

To conclude, we’ve covered a few different ways to rip wood. It doesn’t matter which method you choose it will be hard work, but nothing fills you with a sense of pride more than holding in your hand a workpiece that you've made yourself, completely by hand.