- Why are sharpening stones used with a liquid and not dry?

- Why are different liquids used?

- Which sharpening stone is suitable for which tools?

- Which sharpening stones are more convenient?

- Where do oilstones and waterstones come from?

- What are the typical characteristics of oil and water stones?

- Are there stones that can be used with oil and water?

- What influence does the steel have on the selection of oil or water stones?

What is the difference between oil and water sharpening stones? When is one sharpening system better to use than the other? What are the differences between oil stones and water stones? These are the questions we will explore in more detail below.

Why are sharpening stones used with a liquid and not dry?

Many assume that the liquid serves as a lubricant during sharpening. Of course, the use of water or oil facilitates the movement of the tool on the stone surface. However, the main reason for using fluids is that they prevent the abrasion from the tool and stone from settling on the stone surface. Without the liquid, the abrasion would settle between the grinding particles and prevent the particles from touching the steel and the stone from working effectively

Bench stones are moistened with liquid during sharpening

Why are different liquids used?

Why are some stones used with oil and others with water? Some stones do not work with water because they either clog quickly when used with water or because water drips off their surface. This includes, for example, the Arkansas stones from the US state of the same name, which clog very quickly when used with water.

Which sharpening stone is suitable for which tools?

Oilstones are usually harder, which is why their surface does not deteriorate as quickly. They remain flat for longer, and tools that have a very small contact surface on the stone leave fewer grooves or scratch marks in the stone surface. This is why oilstones are very popular with sculptors, whose carving tools often have very rounded cutting edges. Due to the higher stability of the stones, they can be used to make filigree moulding stones (5-piece set), which are necessary for sculpting tools to remove the inner sides.

Due to their high hardness, however, the oilstones work more slowly. With the comparatively softer waterstones, used, dull abrasive particles break out of the surface more quickly and make room for fresh, sharp particles. This means that waterstones always have full abrasive power and are therefore faster or more efficient in removing material. However, the softer bond also makes waterstones wear out much faster, which is why they need to be trued more frequently.

Which sharpening stones are more convenient?

The liquid used also brings differences in the use of the stones. Oil works very well in the workshop. For on the road, water is easier to handle. Water is available almost always and everywhere and is much cheaper than oil. It makes less mess and does not leave stains. In the outdoors, it is much easier to work with waterstones. A typical example is the whetstone for sharpening scythes.

Water causes corrosion very quickly in rusting steels (carbon steel). Since most tools are made of such steel, the water must be removed without leaving any residue after sharpening, or the tool blade must be dried well. Oil, on the other hand, prevents rusting.

Where do oilstones and waterstones come from?

There are regional differences in whether oil or water is used. Originally, only natural stones were used for sharpening. In the English-speaking area, USA and GB, the Arkansas stones, which originate from the USA, are widely used. There, sharpening with oilstones is still very common, while the Belgian Whetstones (waterstones that come from Belgium) were found in almost every old carpenter's workshop in our country. That is why we mostly use waterstones for sharpening.

What are the typical characteristics of oil and water stones?

Oilstones. Of the Arkansas stones mentioned above, there are very fine-grained specimens with which the edge can be polished very well. They are very popular as polishing stones. If such an oilstone is used for honing the edge, it makes sense to also use oilstones for the preparatory work. However, the coarser variants of Arkansas stones are very soft, which is why synthetically manufactured stones have become popular for this purpose. One manufacturer of such synthetic oilstones is the Norton company. Norton stones, however, are relatively coarse and the grain size gap to the Arkansas whetstones is quite large. This gap is closed by Kunsuto oilstones with medium grains.

Typical representatives of oilstones

To maintain oilstones, they should be cleaned from time to time. It is best to use petroleum or turpentine substitute for this purpose. Trueing of hollow-ground oilstones is done in the same way as for waterstones, with trueing plates or water sandpaper. However, you should use one of the solvents mentioned above for trueing.

Waterstones. The Belgian Whetstone as a natural stone has already been mentioned. This is a very fine honing stone with very good removal and polishing properties. Since the rock layers from which the Belgian Whetstone come are very thin, the whetstones are glued onto a carrier of slate stone. The darker slate stone only serves as a carrier and is not suitable for sharpening or polishing. Rectangular Belgian whetstones are now rare and expensive, mostly irregularly shaped fragments are found. Very good natural stones with different grain sizes also come from Japan. Because of the greater homogeneity and purity of the abrasives, artificially produced benchstones have prevailed among the waterstones.

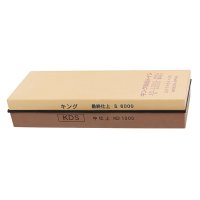

Soft- and hard-bound waterstones from different manufacturers

Sun Tiger/King stones are the most widely used. They are very soft and ideally suited for the pure carbon steels used in Japan. Due to their soft bond, they are very fast, but need to be trued frequently. Other Japanese manufacturers also produce stones with different hardnesses. Shapton offers comparatively hard-bonded stones for waterstones. Shapton stones (e.g., Glass Stones Set) give a very soft sharpening feeling even in the finest grits, despite their very fast abrasion.

Are there stones that can be used with oil and water?

One manufacturer of such stones is Missarka (Missarka Combination Stone, Grit 150/1200 and Missarka Combination Stone, Grit 1200/4000). These are also hard-bonded and can be used with both oil and water. However, you should stick with the chosen liquid once you have decided. Switching from water to oil may still be possible (stone must dry completely). However, the other way round, from oil to water, is very time-consuming (the stone has to be cleaned with solvents).

What influence does the steel have on the selection of oil or water stones?

The alloy components of high-alloy steel types are often very coarse-grained, which wears out the soft stones quickly. This is counteracted by a harder bond, which would argue for the use of oilstones. In the meantime, however, there are also very good, hard-bonded waterstones that are suitable for sharpening high-alloy steel grades. Whether oil or waterstones are used is therefore up to each person and depends on their preferences and requirements.